Manufacturing Processes & Routes

Processes and Routes detail the various stages of manufacturing a product. A route is assigned to a Bill of Materials and Processes are assigned to a route.

A route can have a single or multiple processes, you can also set different processes on a route depending on how many products are being manufactured. This is useful when smaller production runs use a different process to larger manufacturing runs.

Whilst assigning a route to a Bill of Materials is essential, the routes and processes functionality is generally more informative than impactive on how Planufac works. In future releases we hope to expand the routing functions to assist with planning your production schedules.

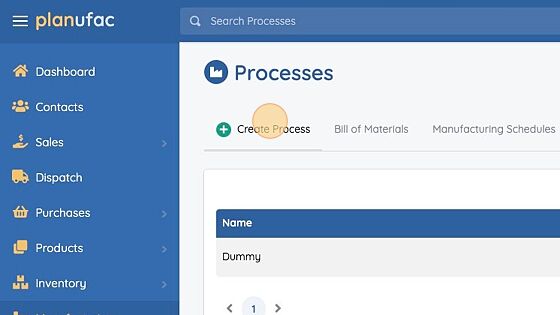

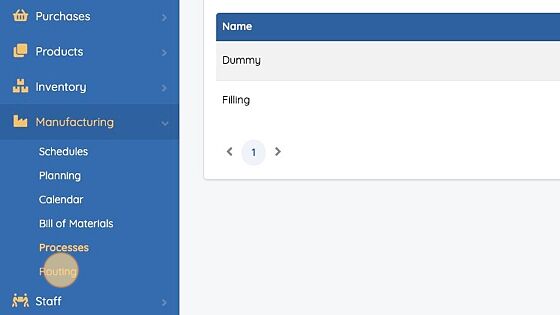

If you do not want to configure routes and processes, you can simply create a "dummy" process and assign it to a "dummy" route which can be applied to your Bill of Materials.

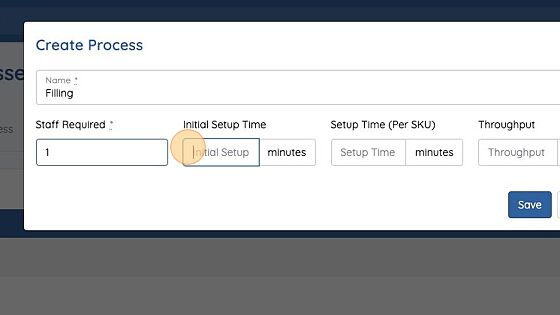

How to create a process

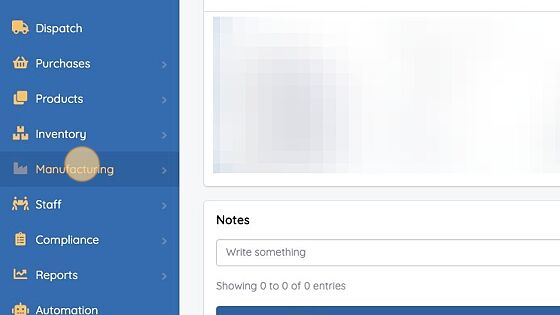

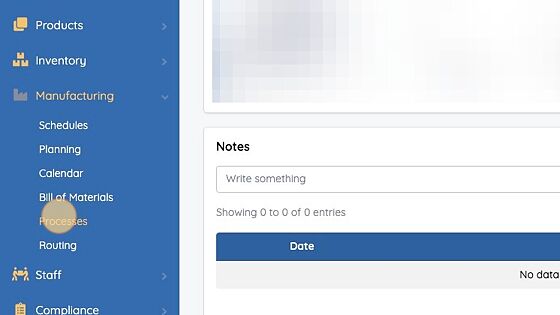

1. Click "Manufacturing"

2. Click "Processes"

3. Click "Create Process"

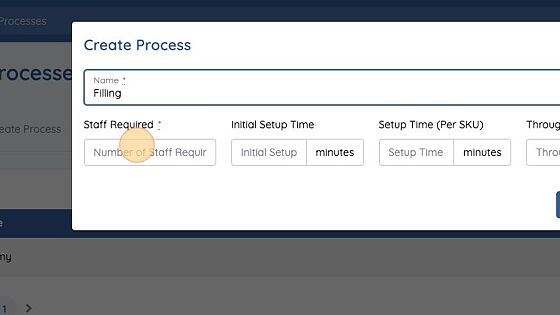

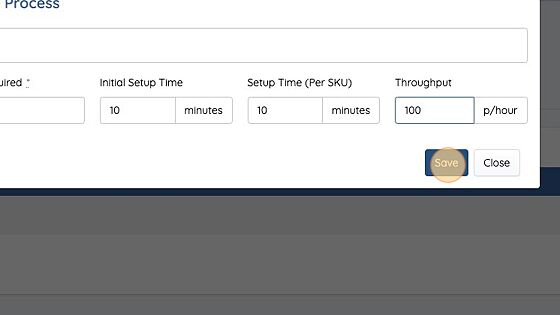

4. Enter the information about the process:

The fields as follows:

Staff required: how many members of staff are required for this process

Initial setup time: how much time is required to setup this process

Setup time (per SKU): how much time is needed when changing between SKU's in the same schedule

Throughput: how many units this process is capable of producing per hour.

5. Click "Save"

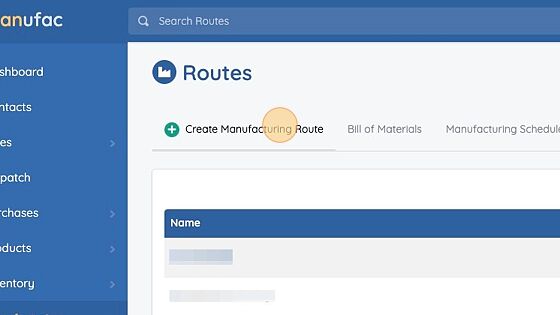

How to create a Route

1. Click "Routing"

2. Click "Create Manufacturing Route"

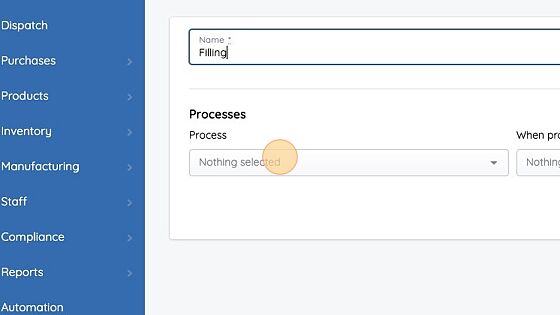

3. Enter a name for your route and choose a process

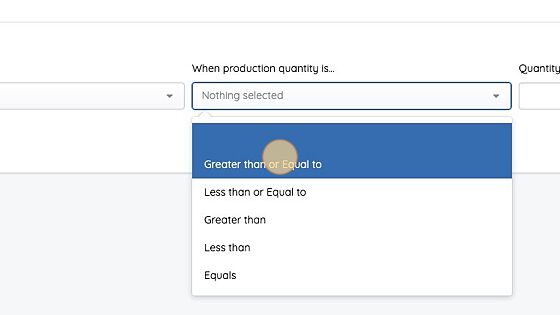

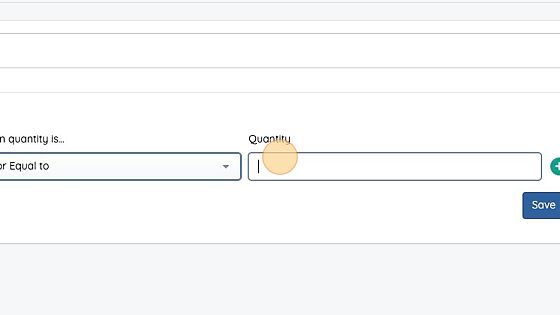

4. The process can be dependant on the quantity being manufactured, in some cases you may want to use a different process for higher/lower quantities. If the process is the same for all quantities select "Greater than or Equal to" and enter 0 as the quantity.

5. Enter a quantity (see point 4 above for additional info)

You can add additional processes by clicking the + icon next to an existing process.